Heat sinks are essential components in various electronic devices, helping to manage heat and prevent overheating. Among the various types of heat sinks, skived heat sinks stand out for their efficiency and performance. In this guide, we will explore skived heat sinks, their manufacturing process, and their applications in different industries.

PTHeatsink, a leading heat sink manufacturer with facilities in the USA and China, has been at the forefront of thermal solutions since 2003. With extensive expertise and a commitment to quality, PTHeatsink serves a wide range of industries, including storage energy, solar inverters, automobiles, computer servers, data centers, artificial intelligence, telecommunication, and medical equipment.

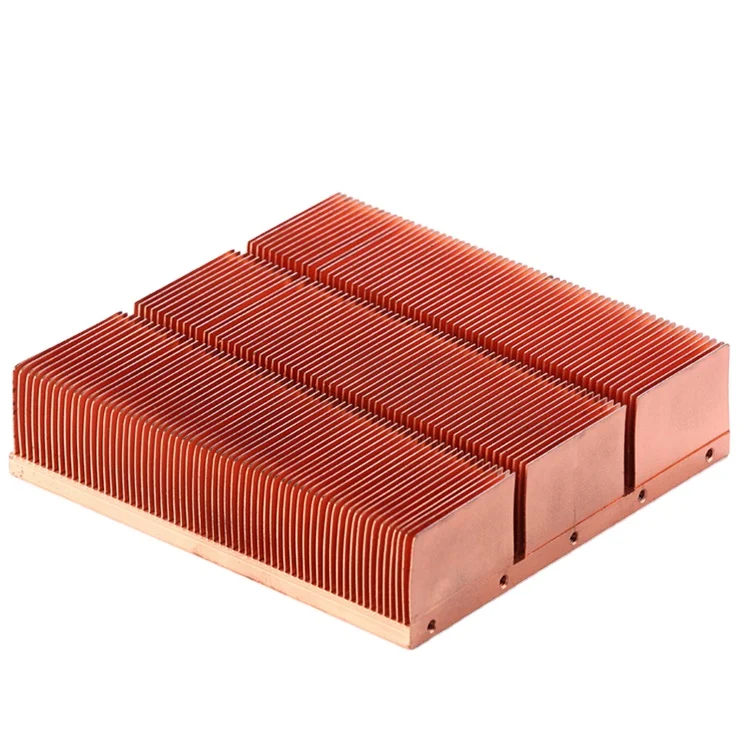

What are Skived Heat Sinks?

Skived heat sinks are specialized cooling devices used to dissipate heat from electronic components. They are made using a unique manufacturing process called skiving, which involves slicing thin fins from a block of metal. These fins increase the surface area, allowing for more efficient heat dissipation.

Comparison with Other Heat Sinks:

- Extrusion Heat Sinks: Made by forcing metal through a die, extrusion heat sinks are cost-effective but less efficient than skived heat sinks.

- Heat Pipe Heat Sinks: Utilize heat pipes to transfer heat, offering high performance but at a higher cost.

- Die Cast Heat Sinks: Suitable for mass production with high-speed filling and short cycle times, but with lower thermal performance.

- Forged Heat Sinks: Offer high thermal conductivity and low density, ideal for weight-sensitive applications.

Key Advantages of Skived Heat Sinks:

- High thermal performance due to increased surface area

- Flexibility in design for various applications

- Cost-effective manufacturing process

Skiving Technology

Skiving is a precise manufacturing process used to create thin, closely spaced fins from a solid block of metal. This technology allows for the production of heat sinks with superior thermal performance.

Tools and Materials:

- Skiving Machines: Specialized machines with sharp blades to slice the metal.

- Materials: Typically aluminum or copper, known for their excellent thermal conductivity.

Advantages of Skiving Technology:

- Creates high-density fins for maximum heat dissipation

- Allows for custom designs tailored to specific applications

- Provides a cost-effective solution compared to other manufacturing methods

Manufacturing Process of Skived Heat Sinks

The manufacturing process of skived heat sinks involves several steps to ensure high quality and performance.

Step-by-Step Description:

- Material Selection: Choosing the right metal, usually aluminum or copper.

- Initial Cutting and Shaping: Preparing the metal block for skiving.

- Skiving the Fins: Using skiving machines to slice thin fins from the metal block.

- Post-Skiving Treatments: Applying surface treatments to enhance performance and durability.

- Finishing: Final inspections and adjustments to ensure quality.

Quality Control Measures:

- Regular inspections during each manufacturing stage

- Testing for thermal performance and structural integrity

- Ensuring adherence to design specifications

Applications of Skived Heat Sinks

Skived heat sinks are used in various industries to manage heat in electronic devices. PTHeatsink’s skived heat sinks are trusted by leading brands like LG, HP, and Stellantis for their reliability and performance.

Industries That Benefit:

- Storage Energy: Efficient cooling solutions for energy storage systems.

- Solar Inverters: Managing heat in solar power systems to ensure efficiency.

- Automobiles: Cooling electronic components in vehicles.

- Computer Servers: Essential for managing heat in data centers.

- Data Centers: Ensuring optimal performance of servers and data storage devices.

- Artificial Intelligence: Cooling high-performance computing systems.

- Telecommunication: Managing heat in network equipment.

- Medical Equipment: Ensuring the reliability of medical devices.

Case Studies:

- LG Electronics: Implementation of skived heat sinks in their high-performance displays.

- HP Servers: Enhanced cooling solutions for their data center servers.

- Stellantis: Efficient thermal management in their electric vehicles.

Designing Efficient Heat Sinks

Designing an efficient heat sink involves considering several factors to ensure optimal performance. PTHeatsink’s seasoned engineers use advanced tools and software to design custom heat sinks.

Key Factors in Design:

- Thermal Requirements: Understanding the heat dissipation needs of the device.

- Material Selection: Choosing the right material for maximum efficiency.

- Fin Design: Optimizing the shape and density of fins for better performance.

Software and Tools:

- CFD (Computational Fluid Dynamics): Computational Fluid Dynamics For analyzing heat flow and performance.

- Solidworks, ProE, and AutoCAD: For precise design and modeling.

Customization Options:

- Custom shapes and sizes to fit specific applications

- Surface treatments for enhanced performance

- Integration with other cooling technologies like heat pipes and vapor chambers

PTHeatsink’s Expertise and Capabilities

PTHeatsink is renowned for its expertise in thermal management solutions. With a state-of-the-art facility and a highly experienced engineering team, PTHeatsink offers unparalleled quality and performance.

Overview of Facilities:

- 91,000 square feet facility with advanced manufacturing capabilities

- Comprehensive production processes, including CNC machining, extrusion, stamping, cold forging, die casting, skiving, heat pipe assembly, water cooling plate manufacturing, friction stir welding, vapor chamber production, and thorough inspection and packaging.

Experience and Qualifications:

- Bachelor degree engineers with over 10 years of experience

- Successful completion of over 3,000 designs

Unique Selling Propositions:

- Competitive Pricing: Cost-effective solutions without compromising quality

- Premium Support: Professional sales team providing seamless communication

- Trusted by Leading Brands: Serving small enterprises and world-class brands like LG, HP, Growatt, and Escatec

Benefits of Partnering with PTHeatsink

Partnering with PTHeatsink offers numerous benefits, ensuring that your thermal management needs are met with high-quality solutions.

One-Stop Solution:

- From design to full production, PTHeatsink handles every aspect of thermal management solutions.

Cost-Effectiveness:

- Competitive pricing ensures value for money without sacrificing quality.

Seamless Communication:

- Professional and responsive support to address all customer needs.

Long-Term Reliability:

- Trusted by leading brands for consistent quality and performance.

Future Trends in Heat Sink Technology

The field of heat sink technology is constantly evolving, with new trends and innovations emerging.

Emerging Trends:

- Enhanced Materials: Development of new materials with better thermal properties.

- Advanced Manufacturing Techniques: Integration of 3D printing and other advanced technologies.

- Sustainability: Focus on eco-friendly materials and processes to reduce environmental impact.

Innovations at PTHeatsink:

- Continuous investment in R&D to stay at the forefront of thermal management solutions.

- Collaboration with industry leaders to develop cutting-edge technologies.

Importance of Sustainability:

- Commitment to sustainable practices in manufacturing and design.

- Use of recyclable materials and energy-efficient processes.

Skived heat sinks play a crucial role in modern thermal management, offering high performance and cost-effective solutions. PTHeatsink, with its extensive expertise and advanced manufacturing capabilities, is a trusted partner for businesses seeking reliable thermal solutions.

Whether you are in the storage energy, solar inverter, automobile, computer server, data center, artificial intelligence, telecommunication, or medical equipment industry, PTHeatsink has the experience and capabilities to meet your thermal management needs. Partner with PTHeatsink for innovative, high-quality, and cost-effective heat sink solutions.

Frequently Asked Questions

What is a skived heat sink and how does it work?

A skived heat sink is a type of cooling device made by slicing thin fins from a solid block of metal to increase surface area and improve heat dissipation.

How does skiving technology differ from other heat sink manufacturing methods?

Skiving allows for the creation of closely spaced fins, offering better thermal performance compared to other methods like extrusion or die casting.

What are the benefits of using skived heat sinks in thermal management?

Skived heat sinks provide high thermal efficiency, flexibility in design, and cost-effectiveness.

How are skived heat sinks manufactured?

The process involves selecting the right material, cutting and shaping the metal, skiving the fins, and applying post-skiving treatments.

What industries can benefit from skived heat sinks?

Industries such as storage energy, solar inverters, automobiles, computer servers, data centers, AI, telecommunication, and medical equipment can benefit.

How do I choose the right heat sink for my application?

Consider factors like thermal requirements, material selection, and fin design. Consulting with experts like PTHeatsink can help.

What materials are commonly used in skived heat sinks?

Aluminum and copper are commonly used due to their excellent thermal conductivity.

Can PTHeatsink customize heat sinks according to specific requirements?

Yes, PTHeatsink offers customized designs tailored to specific applications and requirements.

What quality control measures are in place during the manufacturing process?

PTHeatsink conducts regular inspections, performance testing, and ensures adherence to design specifications.

What are the emerging trends in heat sink technology?

Trends include the use of enhanced materials, advanced manufacturing techniques like 3D printing, and a focus on sustainability.

What makes PTHeatsink a leading manufacturer in the heat sink industry?

PTHeatsink’s extensive experience, advanced manufacturing capabilities, and commitment to quality set it apart.

What are the unique selling points of PTHeatsink compared to other manufacturers?

Competitive pricing, premium support, and trusted by leading brands.

How does PTHeatsink ensure competitive pricing while maintaining quality?

Efficient manufacturing processes and a large production facility help maintain cost-effectiveness without sacrificing quality.

What kind of support can customers expect from PTHeatsink?

Professional sales team providing seamless communication and responsive support throughout the project.