Introduction

Are you tired of your electronic devices overheating and underperforming? Look no further! In this blog post, we will explore the world of optimizing heat sink performance and uncover strategies for efficient cooling. The importance of heat sink performance in electronic devices cannot be overstated. It directly impacts device longevity and performance.

By understanding the significance of efficient cooling, you can take steps to ensure your devices stay cool, perform at their best, and have a longer lifespan. Get ready to dive into the fascinating realm of heat sinks and discover practical strategies to optimize their performance for efficient cooling.

Understanding Heat Sink Basics

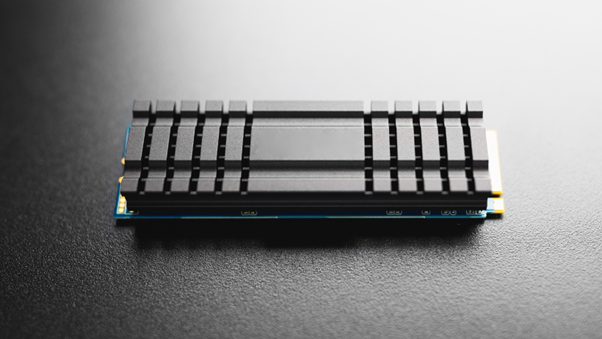

When optimizing heat sink performance, starting with a solid understanding of the basics is essential. Let’s begin by defining what a heat sink is and its purpose. A heat sink is a device designed to dissipate heat generated by electronic components and transfer it to the surrounding environment, thus preventing overheating. Its primary purpose is to maintain safe operating temperatures for the electronic device.

Components and Structure of a Heat Sink

A heat sink comprises various components that work together to dissipate heat efficiently. The most common structure consists of a base, fins, and sometimes a fan for active cooling. The base is usually made of a material with high thermal conductivity, such as copper or aluminum, which transfers heat from the heat source to the fins.

Role of Thermal Conductivity in Heat Dissipation

Thermal conductivity plays a crucial role in heat dissipation. It refers to the ability of a material to conduct heat. Heat sinks with higher thermal conductivity can effectively transfer heat away from the source and into the surrounding environment. Copper, for example, has excellent thermal conductivity, making it a popular choice for heat sink bases.

Heat Sink Materials and Their Properties

Different materials offer varying properties that impact heat sink performance. Aluminum is lightweight, affordable, and offers decent thermal conductivity. On the other hand, copper has higher thermal conductivity but is more expensive and heavier. Depending on specific requirements, other materials like graphite or composite materials may also be used.

Factors Affecting Heat Sink Performance

To optimize heat sink performance, it’s crucial to understand the factors that can affect their efficiency.

Thermal Resistance and Its Impact on Cooling Efficiency

One of these factors is thermal resistance, which measures how much a material impedes heat flow. A lower thermal resistance allows for better heat transfer and, consequently, more efficient cooling. Choosing materials with low thermal resistance is key to improving heat sink performance.

Importance of Proper Heat Sink Sizing and Selection

Proper heat sink sizing and selection are vital in optimizing cooling efficiency. A heat sink that is too small may not have enough surface area to dissipate heat effectively, leading to overheating. Conversely, an oversized heat sink can be inefficient and unnecessarily bulky. Therefore, carefully selecting the right size and type of heat sink for your specific application is crucial.

Effect of Airflow and Heat Transfer Mechanisms

The effect of airflow and heat transfer mechanisms should not be overlooked. Adequate airflow around the heat sink helps carry away the dissipated heat, preventing heat buildup. It’s essential to consider factors like fan placement, ventilation, and air channeling to optimize heat sink performance.

Thermal Interface Materials and Their Role in Heat Transfer

Another critical factor is the selection and proper application of thermal interface materials (TIMs). TIMs improve heat transfer between the heat source and the heat sink. Using high-quality thermal compounds and ensuring proper application and spreading of TIMs can significantly enhance heat sink performance.

Strategies for Optimizing Heat Sink Performance

Several strategies can be implemented to optimize heat sink performance and achieve efficient cooling.

Proper Heat Sink Design and Layout Considerations

One essential strategy is proper heat sink design and layout considerations. This includes factors such as fin geometry and spacing. The shape and arrangement of the fins impact the surface area available for heat dissipation. Additionally, the heat sink’s base thickness and surface area play a role in heat transfer efficiency. Optimizing these design aspects can significantly improve cooling performance.

Enhancing Heat Sink Airflow and Cooling Mechanisms

Enhancing heat sink airflow and cooling mechanisms is another effective strategy. Selecting the right fan and placing it strategically can improve airflow, aiding heat dissipation. Proper airflow management and channeling techniques ensure that cool air reaches the heat sink and hot air is efficiently expelled. Integrating heat pipes into the heat sink design can also enhance heat transfer capabilities, allowing for more effective cooling.

Thermal Interface Optimization Techniques

Optimizing the thermal interface is crucial for efficient heat transfer. It involves using high-quality thermal interface materials (TIMs) that have low thermal resistance. Proper application and spreading of thermal compounds between the heat sink and the heat source are essential to ensure optimal heat transfer. Additionally, considering alternative TIMs, such as thermal pads or phase-change materials, can benefit specific applications.

Advanced Cooling Techniques for Heat Sink Optimization

Several options are available for those seeking even more advanced cooling techniques to optimize heat sink performance.

Liquid Cooling Systems and Their Benefits

One such technique is the implementation of liquid cooling systems. Liquid cooling involves using a liquid, such as water or liquid metal, to remove heat from the heat sink. This method offers superior heat dissipation capabilities compared to traditional air cooling. We’ll explore the types of liquid cooling solutions, their benefits, and how they can be integrated with heat sinks for optimal cooling efficiency.

Phase-Change Cooling Methods

Another innovative cooling method is phase-change cooling. This technology utilizes the phase transition of a liquid or a refrigerant to absorb and dissipate heat. Heat pipes and vapor chambers are commonly employed in phase-change cooling systems. Heat pipes are sealed copper tubes that use the evaporation and condensation of a working fluid to transfer heat efficiently.

Vapor chambers, on the other hand, consist of a flat, thin plate filled with a vaporizable liquid, enabling high heat transfer rates. We’ll delve into the overview of phase-change cooling, its applications with heat pipes and vapor chambers, and the benefits and considerations associated with this cooling method.

Advanced Materials and Technologies for Heat Sinks

Furthermore, advanced materials and technologies are being explored to enhance heat sink performance. Graphene-based heat sinks, leveraging the exceptional thermal conductivity of graphene, hold promise for efficient heat dissipation. Thermoelectric cooling devices, capable of heating and cooling, offer an alternative approach to conventional cooling methods.

Additionally, nanofluid-based heat sink enhancements, where nanoparticles are dispersed in a fluid, have shown potential in improving heat transfer. We’ll explore these advanced materials and technologies, discussing their advantages and potential applications in heat sink optimization.

Testing and Evaluation of Heat Sink Performance

Testing and evaluation are essential steps to ensure efficient cooling when optimizing heat sink performance.

Importance of Performance Testing and Analysis

Performance testing and analysis allow you to assess your heat sink’s effectiveness and identify improvement areas. By conducting thorough testing, you can gather valuable data and insights to help you make informed decisions to enhance cooling performance.

Key Metrics for Evaluating Heat Sink Efficiency

Several key metrics are used to evaluate heat sink efficiency. These metrics include thermal resistance, thermal conductivity, and heat transfer coefficient. Thermal resistance measures how well the heat sink dissipates heat, while thermal conductivity quantifies the material’s ability to transfer heat.

The heat transfer coefficient indicates the heat transfer rate from the heat sink to the surrounding environment. By evaluating these metrics, you can comprehensively understand the heat sink’s performance and identify any areas that require optimization.

Test Methods and Tools for Heat Sink Evaluation

To evaluate heat sink performance, various test methods and tools are available. Thermal imaging allows you to visually assess the temperature distribution across the heat sink, enabling the identification of hotspots and areas of heat dissipation inefficiencies. Thermocouple measurements involve placing temperature sensors in critical areas to measure heat transfer and temperature differentials. Computational fluid dynamics (CFD) simulations utilize mathematical modeling to simulate fluid flow and heat transfer, providing valuable insights into heat sink performance under different conditions.

Case Studies and Real-World Examples

Here are some real-life examples and case studies showcasing the application of heat sink optimization:

Intel

Intel, a leading semiconductor manufacturer, implemented advanced heat sink optimization techniques in their processors to improve cooling efficiency and prevent overheating. This allowed for higher clock speeds and enhanced performance in their CPUs.

BMW

BMW implemented heat sink optimization strategies in their electric vehicles to manage battery temperature and improve efficiency. By integrating advanced heat sink designs with liquid cooling systems, BMW enhanced battery performance and extended the driving range of their electric vehicles.

Google Data Centers:

Google optimized heat sink performance in their data centers by implementing innovative cooling techniques like liquid and airflow management. This led to increased energy efficiency and reduced cooling costs while maintaining optimal server performance.

Conclusion

Optimizing heat sink performance is essential for efficient cooling in electronic devices. You can significantly improve cooling efficiency by understanding the basics of heat sink design, considering factors like thermal resistance and proper sizing, and implementing strategies to enhance airflow and thermal interface.

Exploring advanced cooling techniques and learning from real-life examples and case studies further expands your knowledge and provides practical insights. Continuous improvement and adaptation to emerging technologies are key in the ever-evolving field of heat sink optimization. By implementing these strategies, you can ensure optimal heat dissipation, prolong device lifespan, and maximize performance in your electronic devices.

Contact Us Today for the most effective heat sink manufactured for your devices.