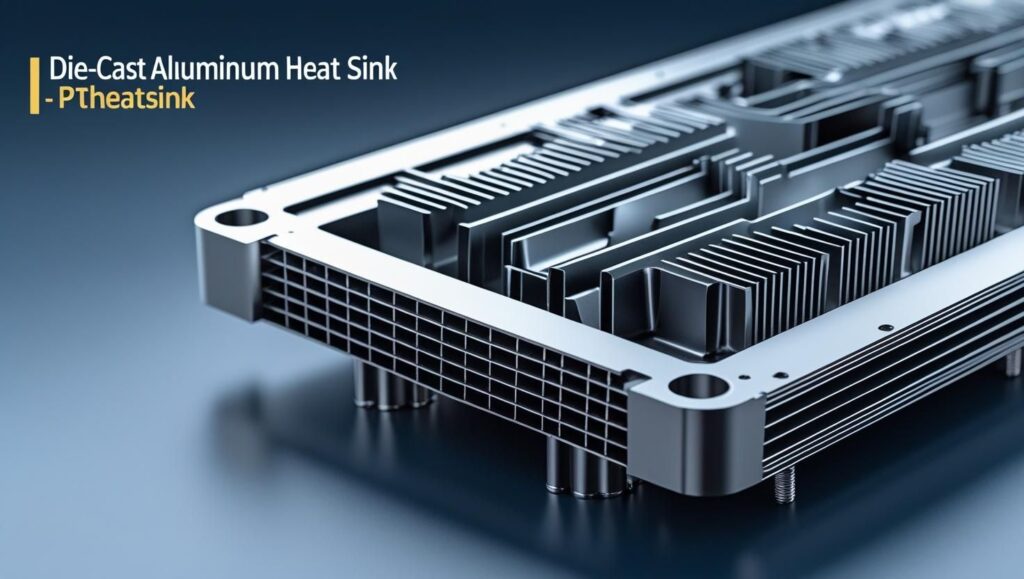

Die-casting aluminum heat sinks offer better thermal performance, strength, and affordability — ideal for thermal designs that need more than the absolute minimum.

In thermal management, that of electronics, power devices, or lighting, the heat sink is paramount. The key to a good design begins with the correct material and process. Extrusion heat sinks are the norm with a balance of cost, conductivity, and tolerability. But when performance is combined with precision, die-cast aluminum takes over. And the actual difference usually depends on who makes them; your heatsink manufacturer of choice is the deciding factor in achieving it.

Why Aluminium Profiles for Heat Sinks Make Sense

The most commonly used material for heat sinks is aluminum, for several very good reasons. It has a high thermal conductivity-to-weight ratio that is effective without the weight or expense. Aluminum is also resistant to corrosion, easy to finish, and can be used in both passive and active cooling designs.

Die-cast aluminum heat sinks, in particular, enable shapes and features that extrusion may not always be able to provide. If your technology demands fine detail, mounting capabilities, or close geometry, die casting enables it. It can result in improved airflow, reduced thermal resistance, and easier assembly. Where your technology must rely on solid performance, these small design advantages are enormous benefits.

How a Quality Heatsink Maker Delivers Real Value

This is where theory meets practice. A good heatsink manufacturer does not merely make parts. They help engineers design better concepts from the ground up.

A quality maker will be aware of the difference between technically adequate and reliably effective solutions in real-world conditions. They will ask you the right questions about mounting surfaces, airflow direction, power density, and operating temperatures.

Armed with that information, they can guide you toward a die-cast or extrusion heat sink design that aligns with your product goals rather than your thermal limitations.

You can count on your manufacturing partner to offer support in thermal simulation, design optimization, surface treatment, and post-processing. Some companies excel at collaborating with customers to design profiles that dissipate heat efficiently and meet mechanical and production requirements effectively.

Comparing Heat Sink Types

There are several methods of creating a heat sink, and the best option for you will depend on your particular requirements. Here is a brief rundown:

Extrusion forms long profiles with uniform cross-sections. Extrusion is a cost-effective and ideal solution for situations where shape and length can be standardized. This method is ideal when the airflow direction and surface area remain constant.

Machining is a precise process that is ideally suited for low-volume runs or highly specialized parts. It’s typically more expensive due to material waste and labor.

Die casting enables the production of complex geometries and the addition of features such as built-up mounting holes or intricate fin patterns. It’s best suited for use where a small size and increased production volume are required. It also offers improved dimensional stability and can aid assembly by lowering the number of discrete parts.

The lesson here is straightforward. In situations where complexity, performance, and consistency are critical, die-cast aluminum is most likely the superior long-term solution. And a capable heatsink producer is the difference between mediocre and the best.

When Die-Cast Aluminium is the Ideal Choice

Die-cast aluminum heat sinks are not the solution for all designs, but they do offer some benefits that are suitable for most purposes. When space restrictions exist, airflow restrictions are present, or other structural integration needs arise, die casting can provide the precision and performance you need.

Utilize die-cast aluminum when:

- Your design has restricted airflow and close spatial limitations

- Aesthetic finish and product presentation are important

- You need to include such information as fasteners or mounting points

- Your project is for mid- to high-level manufacturing, and you prioritise long-term cost-effectiveness.

In LED lighting, for instance, fixtures must be clean-looking, durable, and cool-running. All three can be replicated in a die-cast heat sink without a trade-off. Your idea can be taken from your mind and developed into an effective thermal solution by an experienced heatsink manufacturer.

What to Look for When Purchasing an Extrusion Heat Sink Supplier

This is not simply a matter of getting a company to ship on time. The proper heatsink manufacturer will be proactive, not reactive. They will inquire about your target environment, your enclosure design, and even your installation process. The idea is to eliminate surprises once production has begun.

The following is what an ideal supplier should provide:

- In-depth understanding of aluminum alloys and their thermal characteristics

- Ability to provide both generic profiles and specifically designed extrusions

- Even surface finish and milling quality

- Established quality control and thermal validation methods

- Transparent communication and engineering support during development

Final Thoughts: Choose Smarter. Build Better.

Thermal performance plays a crucial role. It has a direct impact on product life, reliability, and end-user safety. Die-cast aluminum heat sinks enable you to design with less compromise by providing flexibility, thermal performance, and cost control in one solution. However, the true secret lies in selecting the proper heatsink manufacturer.

You want an individual who sees the forest, not the trees. We offer engineering expertise, high-quality manufacturing, and a collaborative spirit that supports each stage of development. So, are you ready to improve your thermal design? Don’t delay. Contact us today for trusted guidance, tailored solutions, and high-performance heat sinks that bring your aspirations to life from the inside out.

FAQs

What is the benefit of a die-cast aluminum heat sink?

Die-casting heat sinks accommodate intricate geometries and integrated features, providing improved thermal performance and a mechanical fit in compact constructions.

How does an extrusion heat sink work?

It radiates heat away from elements into the ambient air via convection and conduction, aided by expanded surface contact and air movement.

Is aluminum or copper better as a heat sink?

Copper is a better conductor of heat but is heavier and more expensive. Aluminum is more commonly used because it is lighter, less expensive, and has sufficient performance for most applications.

Can I get a heat sink design tailored to my product?

Yes. All the major manufacturers stock custom designs, i.e., die-cast and extruded profiles specially designed to your product size, power load, and airflow conditions.

Which industries utilize extrusion heat sinks most frequently?

Applications include power electronics, automotive, industrial automation, telecommunications, and LED lighting. Wherever a thermal issue is present, extrusion heat sinks are at work.