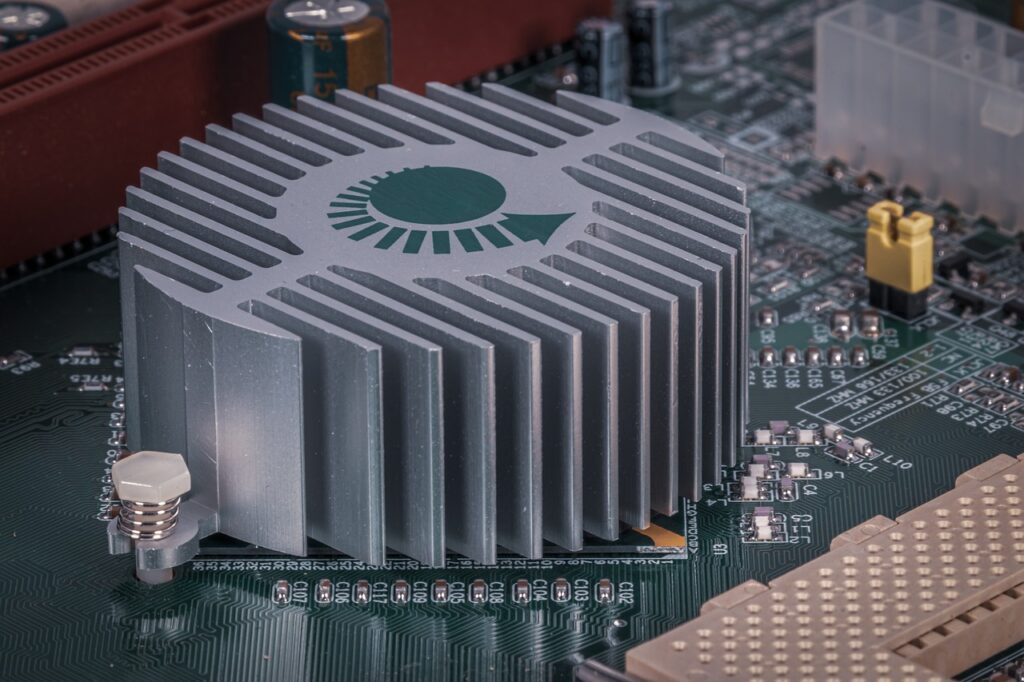

When it comes to cooling electronic devices, heat sinks play a crucial role in ensuring they don’t overheat. But not all heat sinks are created equal. The material used in a heat sink can greatly impact its performance, efficiency, and cost. Among the various materials available, aluminium stands out as the go-to choice. In this article, we’ll explore why aluminium is preferred over other materials for heat sinks, its benefits across different industries, and how companies like PTHeatsink leverage aluminium to create effective cooling solutions.

Why Aluminium is Preferred for Heat Sinks

Thermal Conductivity

Aluminium is widely chosen for heat sinks due to its excellent thermal conductivity. Although copper has a higher thermal conductivity, aluminium strikes an optimal balance between heat dissipation and weight. This means aluminium can efficiently transfer heat away from critical components without adding significant weight, making it ideal for a wide range of applications.

Lightweight Nature

One of the standout features of aluminium is its lightweight nature. Aluminium is about one-third the weight of copper, making it much easier to handle and install, especially in applications where weight is a critical factor, such as in aerospace and automotive industries. The reduced weight also contributes to lower shipping costs and easier manufacturing processes.

Cost-Effectiveness

In addition to being lightweight, aluminium is also more affordable than many other metals. This cost-effectiveness makes it an attractive option for large-scale production, where keeping costs down without compromising on performance is key. Aluminium’s abundant availability and relatively low cost compared to materials like copper or silver make it the material of choice for heat sink manufacturers.

Corrosion Resistance

Another significant advantage of aluminium is its natural corrosion resistance. When exposed to air, aluminium forms a thin oxide layer that protects it from further oxidation. This makes aluminium heat sinks durable and long-lasting, especially in environments where moisture or chemicals might be present. This corrosion resistance is particularly beneficial in industries such as telecommunications and outdoor electronic systems.

Comparing Aluminium to Other Materials

Aluminium vs. Copper

While copper is often touted for its superior thermal conductivity, aluminium offers several advantages that make it a more practical choice in many applications.

- Thermal Conductivity Comparison: Copper has a thermal conductivity of about 400 W/mK, while aluminium’s is around 235 W/mK. However, aluminium’s lower density means it can achieve similar cooling performance at a fraction of the weight and cost.

- Cost and Weight Comparison: Aluminium is significantly lighter and cheaper than copper. For instance, a typical aluminium heat sink might weigh half as much as a copper one, making it easier to integrate into designs where weight savings are crucial, such as in laptops and mobile devices.

- Application Scenarios: Aluminium is preferred in applications where weight, cost, and ease of manufacturing are more critical than achieving the absolute best thermal conductivity. Copper is reserved for situations where maximizing thermal performance is paramount, such as in high-end CPUs or GPUs.

Aluminium vs. Other Alloys

Aluminium is also compared with other alloys like zinc, brass, and steel. Each has its own set of advantages, but aluminium often comes out on top due to its excellent combination of properties.

- Zinc: While zinc offers good casting properties, it is heavier and less thermally conductive than aluminium. This makes aluminium a better choice for heat sinks that need to be lightweight and efficient.

- Brass and Steel: Both materials are more robust but also heavier and less thermally efficient than aluminium. These are typically used in situations where structural strength is more important than heat dissipation, such as in mounting brackets or enclosures.

Aluminium in Different Types of Heat Sinks

Extruded Heat Sinks

Extruded aluminium heat sinks are one of the most common types, thanks to the metal’s excellent machinability and ductility. The extrusion process involves pushing aluminium through a die to create the desired shape, which is then cut to the required size. This method is highly efficient and cost-effective, allowing for the production of complex shapes that optimize airflow and heat dissipation.

Die-Cast and Forged Heat Sinks

Die casting involves forcing molten aluminium into a mold under high pressure, creating a highly detailed and precise part. Forging, on the other hand, involves shaping aluminium under extreme pressure, which improves its structural integrity. Both methods are excellent for producing heat sinks with complex geometries that are not achievable through extrusion alone.

- Application Example: In the automotive industry, die-cast aluminium heat sinks are used to cool power electronics in electric vehicles. The ability to create intricate shapes means these heat sinks can be designed to fit into tight spaces without compromising performance.

Skived Fin Heat Sinks

Skiving is a manufacturing process where thin fins are sliced from a single piece of aluminium, creating high-density fin structures that enhance thermal performance. Skived fin heat sinks offer a superior surface area for heat dissipation, making them ideal for applications requiring high thermal efficiency in a compact form factor.

Heat Pipe and Vapor Chamber Integration

Aluminium heat sinks can be integrated with heat pipes and vapor chambers to further enhance thermal management. Heat pipes and vapor chambers work by transferring heat more efficiently across the heat sink, improving overall cooling performance.

- Application Example: In data centers, aluminium heat sinks with embedded heat pipes are used to manage the intense heat generated by high-density server racks. This integration allows for more effective cooling without the need for bulky, expensive cooling systems.

Design Flexibility and Customization

Ease of Machining

One of aluminium’s greatest strengths is its ease of machining. Aluminium can be easily cut, drilled, and shaped into complex designs, allowing for a high degree of customization. This flexibility makes it possible to create heat sinks tailored to specific applications, whether they require intricate fin designs or specific mounting configurations.

Surface Treatments and Finishes

Aluminium heat sinks can undergo various surface treatments to improve their performance and appearance. Anodizing, for example, not only enhances corrosion resistance but also allows for color customization, making it easier to integrate heat sinks into the overall design of a product.

- Example: PTHeatsink offers anodized aluminium heat sinks that provide both enhanced durability and aesthetic appeal. These heat sinks are particularly popular in consumer electronics, where the appearance of internal components can be a selling point.

Applications Across Industries

Telecommunication and Data Centers

In the telecommunications and data center industries, where equipment runs 24/7, effective thermal management is crucial. Aluminium heat sinks are widely used in these fields due to their ability to efficiently dissipate heat while being lightweight enough to not overburden the infrastructure.

Automotive Industry

In the rapidly evolving automotive industry, particularly with the rise of electric vehicles (EVs), aluminium heat sinks are essential. They are used to cool everything from power electronics to batteries, ensuring these critical components operate within safe temperature ranges. The lightweight nature of aluminium also contributes to the overall efficiency of the vehicles.

Medical Equipment

Aluminium heat sinks are also vital in the medical field, where equipment often needs to operate continuously and reliably. From MRI machines to portable diagnostic devices, aluminium heat sinks help ensure these devices remain cool and operational, reducing the risk of overheating and ensuring patient safety.

Energy Storage and Solar Inverters

In renewable energy systems, such as energy storage units and solar inverters, aluminium heat sinks help manage the heat generated by converting and storing energy. Their corrosion resistance and lightweight properties make them particularly suitable for outdoor and long-term installations.

Sustainability and Environmental Impact

Recyclability of Aluminium

One of the most significant environmental benefits of aluminium is its recyclability. Aluminium can be recycled indefinitely without losing its properties, making it a highly sustainable choice. This contributes to the circular economy, where materials are reused rather than discarded, reducing environmental impact.

Energy Efficiency

Using aluminium in heat sinks also contributes to overall energy efficiency. Aluminium’s ability to dissipate heat effectively means that electronic devices can run cooler and more efficiently, consuming less power and reducing the overall energy footprint.

PTHeatsink’s Expertise with Aluminium Heat Sinks

State-of-the-Art Manufacturing Capabilities

PTHeatsink boasts a state-of-the-art manufacturing facility equipped with the latest technology in CNC machining, extrusion, stamping, cold forging, die casting, skiving fin, heat pipe assembly, water cooling plate, and more. This enables PTHeatsink to produce high-quality aluminium heat sinks that meet the exacting standards of industries worldwide.

Customization and Design Services

PTHeatsink’s seasoned engineering team works closely with clients to design and manufacture heat sinks that meet their specific thermal management needs. Whether it’s for a small startup or a global enterprise, PTHeatsink can deliver custom solutions that optimize performance and cost.

Global Reach and Clientele

With offices in the United States, China, and Singapore, PTHeatsink serves a global clientele, including top-tier brands like LG, HP, and Stellantis. Their expertise and experience make them a trusted partner in the development of cutting-edge thermal solutions.

Quality Assurance and Certifications

Quality is at the heart of PTHeatsink’s operations. The company adheres to stringent quality assurance processes, ensuring that every heat sink produced meets the highest standards. PTHeatsink is also certified in various international standards, further attesting to their commitment to excellence.

Aluminium heat sinks are the go-to choice for many industries due to their excellent thermal conductivity, lightweight nature, cost-effectiveness, and sustainability. PTHeatsink’s expertise in designing and manufacturing custom aluminium heat sinks ensures that their clients receive solutions that not only meet but exceed their thermal management needs. As technology continues to advance, the role of aluminium heat sinks will only become more critical in ensuring the reliability and efficiency of electronic devices across all sectors.

Frequently Asked Questions

1. Why is aluminium more commonly used than copper in heat sinks?

Aluminium is more cost-effective, lighter, and offers sufficient thermal conductivity for most applications.

2. What are the main advantages of aluminium heat sinks?

Key advantages include thermal efficiency, lightweight, cost-effectiveness, and corrosion resistance.

3. How does aluminium’s thermal conductivity compare to other materials?

While not as high as copper, aluminium provides an excellent balance of conductivity, weight, and cost.

4. Can aluminium heat sinks be used in high-performance computing?

Yes, especially when integrated with heat pipes or vapor chambers for enhanced performance.

5. Are there any drawbacks to using aluminium heat sinks?

The primary drawback is lower thermal conductivity compared to copper, but this is often offset by other benefits.

6. How does PTHeatsink ensure the quality of their aluminium heat sinks?

Through stringent quality control processes and certifications, ensuring each product meets industry standards.

7. What industries benefit the most from aluminium heat sinks?

Industries such as telecommunications, automotive, medical, and renewable energy benefit significantly from aluminium heat sinks.