Introduction

Have you ever experienced your electronic devices overheating or failing due to excessive heat? Heat sinks prevent such occurrences by dissipating heat away from sensitive components. However, not all heat sinks are created equal. The thermal conductivity of the material used can significantly affect the performance and efficiency of the heat sink. High thermal conductivity materials, such as metals, diamonds, silicon carbide, and carbon nanotubes, offer numerous benefits regarding thermal management, heat dissipation, and device lifespan. This blog will explore the advantages of using high thermal conductivity materials for your heat sink and their potential applications in various industries.

What Are High Thermal Conductivity Materials?

High thermal conductivity materials are substances capable of efficiently transferring heat from one location to another. These materials are ideal for heat sinks, as they can effectively dissipate heat from electronic components and prevent overheating. Here are some examples of high thermal conductivity materials:

Metals

Metals such as copper and aluminium are some of the most commonly used materials in heat sinks due to their high thermal conductivity, excellent heat dissipation properties, and relatively low cost. Copper, in particular, is a popular choice for high-end heat sinks due to its superior thermal conductivity.

Diamond

Diamond is one of the most thermally conductive materials in existence, with a thermal conductivity value that is five times greater than copper. It is an ideal material for high-performance heat sinks that require rapid heat dissipation.

Silicon Carbide

Silicon carbide is a compound highly resistant to high temperatures, making it an excellent choice for heat sinks requiring high thermal conductivity and durability. It is commonly used in power electronics, aerospace applications, and other high-temperature environments.

Carbon Nanotubes

Carbon nanotubes are a relatively new material with great potential in thermal management applications. They have high thermal conductivity and are incredibly lightweight, making them ideal for space and other weight-sensitive applications. Furthermore, they have a high aspect ratio, which makes them highly effective at dissipating heat.

What Are the Benefits of Using High Thermal Conductivity Materials for Heat Sinks?

Here are the benefits of using high-thermal conductivity materials for heat sinks:

Improved Thermal Management

One of the primary benefits of using high thermal conductivity materials for heat sinks is improved thermal management. These materials can effectively conduct heat away from the source, allowing for more efficient heat dissipation.

Enhanced Heat Dissipation

High thermal conductivity materials also offer enhanced heat dissipation capabilities. Heat sinks made from these materials can effectively dissipate heat into the surrounding environment, preventing devices from overheating and failing. This is particularly important for electronic devices that generate significant heat during operation.

Increased Efficiency and Lifespan of Devices

Using high thermal conductivity materials for heat sinks can also increase the efficiency and lifespan of devices. By preventing overheating and thermal damage, these materials can help devices operate optimally, reducing the risk of failure and extending their lifespan.

Reduced Size and Weight of Heat Sinks

Another advantage of high thermal conductivity materials is their ability to reduce the size and weight of heat sinks. Using materials that conduct heat more efficiently, heat sinks can be designed with smaller footprints and thinner profiles, making them ideal for space-constrained applications. This can also lead to cost savings, as smaller and lighter heat sinks are typically less expensive to manufacture and transport.

What Are the Applications of High Thermal Conductivity Materials in Heat Sinks?

High thermal conductivity materials have numerous applications in heat sinks across various industries. Some of the most prominent ones include:

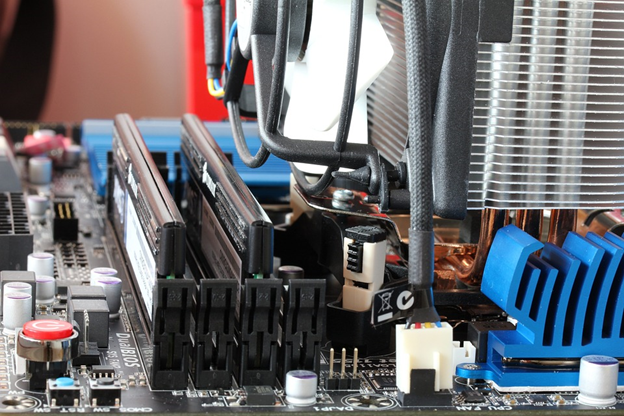

Electronics

Heat management has become a significant concern with the ever-increasing demand for smaller and more powerful electronic devices. High thermal conductivity materials like copper and aluminium are widely used in heat sinks for electronic components such as CPUs, GPUs, and power transistors.

Automotive Industry

The automotive industry is another area where high thermal conductivity materials are crucial. Heat sinks like aluminium and copper dissipate heat generated by engines, brakes, and other critical components. By efficiently managing heat, these materials can help improve fuel efficiency, reduce emissions, and increase the vehicle’s lifespan.

Aerospace Industry

The aerospace industry also relies heavily on heat sinks made of high thermal conductivity materials. In space applications, where there is no air to dissipate heat, materials like diamond and carbon nanotubes can be used for their exceptional thermal properties.

Renewable Energy Systems

Renewable energy systems, such as solar panels and wind turbines, generate significant heat during operation. High thermal conductivity materials, such as silicon carbide, are used in heat sinks to dissipate this heat and prevent damage to the system efficiently.

What Are the Challenges and Limitations of Using High Thermal Conductivity Materials in Heat Sinks?

While high thermal conductivity materials offer many benefits, some challenges and limitations come with their use in heat sinks. Here are some of the main challenges and constraints to consider:

Availability and Cost

One of the main challenges of using high thermal conductivity materials is their availability and cost. Some materials, such as diamond and carbon nanotubes, are relatively rare and expensive. This can make it challenging to scale up production and make it viable for widespread heat sink use.

Fabrication and Processing Difficulties

Another challenge is the difficulty in fabricating and processing high thermal conductivity materials. Some materials, such as diamonds, require specialised equipment and expertise to process. This can add to the cost and complexity of manufacturing heat sinks.

Thermal Expansion Mismatch

Finally, there is the issue of thermal expansion mismatch. High thermal conductivity materials often have different coefficients of thermal expansion compared to the materials they are attached to in the device. This can lead to stress and deformation, which can cause the heat sink to fail over time. Despite these challenges and limitations, research and development are ongoing to address these issues and improve the performance of high thermal conductivity materials in heat sinks.

Conclusion

Using high thermal conductivity materials in heat sink design offers significant benefits in terms of improved thermal management, enhanced heat dissipation, increased efficiency and lifespan of devices, and reduced size and weight of heat sinks.

The range of materials available, including metals, diamonds, silicon carbide, and carbon nanotubes, provides a wide selection of options for various applications, including electronics, automotive, aerospace, and renewable energy systems. However, the challenges of availability and cost, fabrication and processing difficulties, and thermal expansion mismatch must also be considered. Nevertheless, advancements in materials science and processing techniques offer promising opportunities for future development in this field.

Contact Us to purchase a high-quality heat sink with high thermal conductivity material.