Analysis of Mainstream Immersion Liquid Cooling Technology

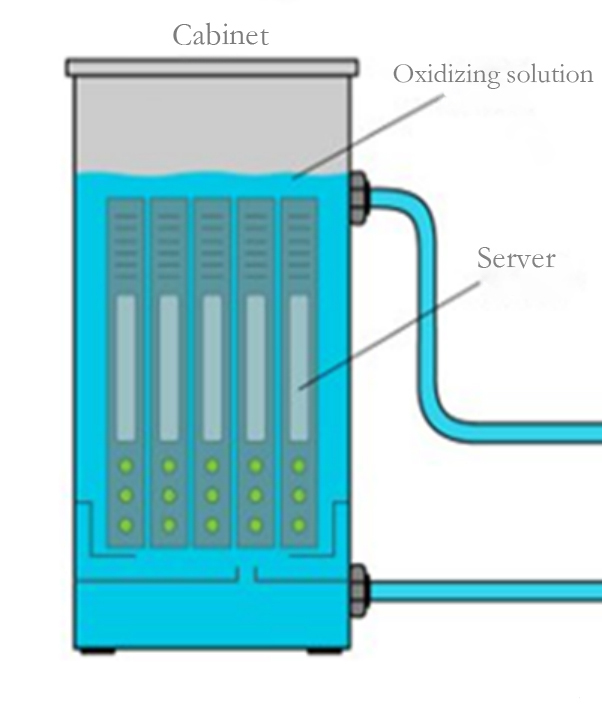

Conventional single-phase immersion liquid cooling

Working Principle:

Servers are vertically mounted and immersed within a sealed cabinet. Coolant enters at the cabinet’s base and returns at the top to achieve a cooling cycle. The coolant flows through the entire space within the plug-in cabinet at a low velocity (≈ natural convection, <0.1 m/s), with a convective heat transfer coefficient on the heat sink fins of only 100–200 W/m²·K.

Heat dissipation performance:

Slightly superior to air cooling. Primary chips such as CPUs and GPUs require the use of VC/heat pipes + heat sinks, with overall performance improving by approximately 20–30% compared to air cooling.

Bottleneck:

Low flow rates constrain the cooling capacity of high-power chips, precluding the use of high-density finned heat sinks. Due to excessive flow resistance in high-density fins, virtually no flow occurs between the fins. Air-cooled heat sinks are bulky, making it impossible to achieve high-density, compact heat exchange.

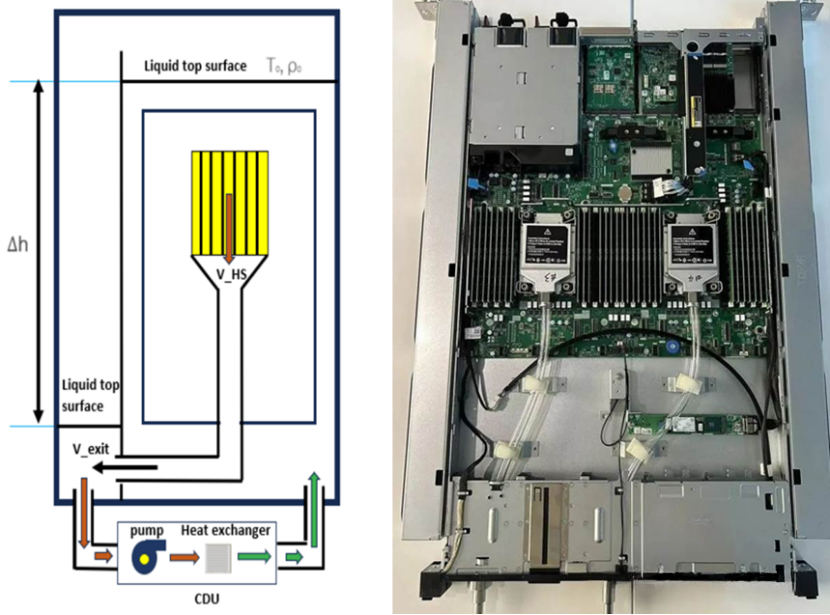

G-flow Differential Pressure-Driven Technology (Intel & H3C)

Breakthrough:

Utilizing the pressure differential generated by the liquid level difference within the cabinet (approximately 1 meter water column), precisely directing coolant flow through the CPU/GPU cold plate via a sealed hose connecting the cold plate and return liquid channel.

Advantages:

Increased flow velocity within the cold plate, allowing for higher pressure differentials, resulting in significantly higher heat transfer efficiency compared to conventional immersion cooling.

Limitations:

Flow rate constrained by cabinet height (pressure differential ceiling ≈ 1m, pure water approx. 9.8 kPa, fluorinated liquid approx. 15 kPa);

Power consumption upgrades require redesigning low-flow-resistance cold plates to overcome flow bottlenecks.

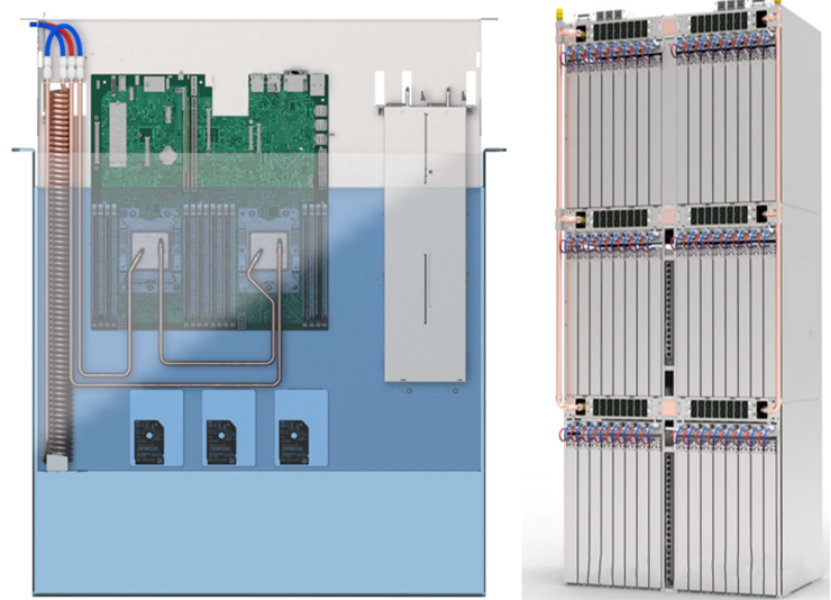

IceoTope Node Pump-Driven Hybrid Immersion Technology

Structure Innovation:

Integrating micro-pumps within chassis nodes, the Manifold+ piping system delivers precise cooling flow to CPU/GPU cold plates. After cooling primary chips, the coolant can submerge and cool secondary heat sources.

Performance Leap:

Pump drive delivers higher head (far exceeding 1m liquid level pressure

differential), with cold plate flow rate/heat dissipation capacity significantly outperforming G-flow.

Core Value:

On-demand traffic adjustment to accommodate dynamic loads of high-power chips

OVHcloud Hybrid Liquid Cooling (Copper Tube Cold Plate + Coil Heat Exchange)

Primary Chip:

Copper tube cold plate with internal water/PG25 coolant circulation, delivering performance comparable to traditional cold plate liquid cooling;

When copper tubes circulate immersion coolant, cooling performance matches Iceotope solutions.

Secondary Chip:

Copper coil heat exchanger regulates immersion fluid temperature.

Features: Addresses differentiated thermal management needs for both high-power cores and low-to-medium power chips.

Comparison of Strengths and Weaknesses of Key Technologies

| Solution | Drive method | Heat transfer performance | Expand Flexibility | Core Limitations |

| Conventional single-phase immersion liquid cooling | Natural convection | ★★☆(≈1.3 times air-cooled) | Low | Low flow velocity, relying on heat sink |

| G-flow Differential Pressure-Driven | Poor liquid level differential pressure | ★★★☆ | Medium | differential pressure≤pump |

| IceoTope Node Pump-Driven | Active Pump Control | ★★★★☆ | High | System complexity increases |

| OVHcloud Hybrid Liquid Cooling | Active cold plate + passive immersion | ★★★★(Main chip) | Medium-high | High complexity of pipeline layout |