Vacuum brazing of aluminum water-cooled plates involves a critical and demanding relationship between vacuum level and brazing pass rate. This process can be understood as a dual-phase operation of “film rupture” and “protection,” where vacuum level plays a decisive role. The vacuum level directly determines the effectiveness of breaking through the stubborn oxide film on the aluminum surface and creates a pure environment for flux flow. It is the primary key factor influencing the brazing pass rate of aluminum cooling plate.

How Vacuum Level Affects Yield Rate

An instantaneous, dense, and stable aluminum oxide film forms on the aluminum surface, preventing liquid brazing filler metal from bonding with the base metal. Vacuum brazing does not use traditional flux; its film-breaking mechanism relies entirely on the vacuum environment and magnesium in the filler metal.

The Relationship Between Magnesium Function and Vacuum Level

Mechanism: Magnesium is present in aluminum brazing filler metal. Under high-temperature vacuum conditions, magnesium volatilizes preferentially into vapor.

Two Key Functions of Magnesium Vapor:

Consuming Oxidizing Gases: Magnesium vapor reacts violently with residual oxygen and water vapor in the furnace, forming magnesium oxide and magnesium nitride, effectively “purifying” the furnace atmosphere.

Directly disrupting oxide films: Magnesium vapor can penetrate aluminum oxide films or reduce them, forming porous magnesium-aluminum spinel. This disrupts the continuity of the oxide film, allowing the liquid flux to wet the base material.

Core Value of Vacuum Level: Magnesium vapor can only be effectively generated and reach the workpiece surface to function under high vacuum conditions. If vacuum is insufficient (excess residual gases), magnesium is largely consumed before reaching the surface, failing to breach the oxide layer and resulting in brazing failure.

Direct defects caused by insufficient vacuum: reduced yield rate

The relationship between vacuum brazing defects and vacuum level is shown in the table below:

| The relationship between vacuum brazing defects and vacuum level | |

| Vacuum brazing defects | Relationship with vacuum level |

| The flux fails to spread and wet | This is the most typical defect caused by insufficient vacuum pressure. The oxide layer remains intact, preventing the flux from contacting the aluminum substrate. Upon melting, the flux forms spherical droplets and fails to create a weld bead. |

| Brazing joint leakage | Insufficient local vacuum (e.g., deep cavities within heat exchangers) causes localized membrane failure, obstructing filler metal flow and preventing complete filling of the brazing joint gap, resulting in a through-defect. |

| Black Contamination | Insufficient vacuum causes magnesium vapor to react with residual gases, producing magnesium oxide and volatile magnesium itself. These substances condense and deposit on the workpiece surface, forming grayish-black stains that compromise both performance and appearance. |

| Corrosion risk | Inadequate vacuum conditions may result in hygroscopic compounds remaining within the brazed joint, potentially triggering electrochemical corrosion during subsequent use and leading to premature failure. |

Key Vacuum Parameters and Control

For aluminum brazing, we focus on two core vacuum metrics:

1.3.1 Ultimate Vacuum Level

Requirement: Vacuum ≤ 5×10-4 Pa (>5×10-4 Pa is preferable)

This reflects the fundamental capability of the vacuum furnace. It indicates the highest vacuum level achievable in an empty furnace and serves as the “entry ticket” for high-quality aluminum brazing.

1.3.2 Key Vacuum Parameters and Control

For aluminum brazing, we focus on two core vacuum metrics:

Working Vacuum (Dynamic Vacuum)

Requirement: Within the critical 450°C to brazing temperature range, vacuum must be stably maintained at ≤ 1 × 10⁻² Pa (ideally better than 6 × 10⁻³ Pa).

Workpieces release significant gases (water vapor, oil vapors, etc.) during heating. The working vacuum level reflects the vacuum system’s capability to maintain high vacuum under severe conditions. If vacuum levels deteriorate sharply (e.g., exceeding 10⁻¹ Pa), it indicates membrane integrity failure, leading to a steep decline in yield rates.

A typical qualified process curve: Evacuate → Low-temperature heating to achieve high vacuum (e.g., 10⁻³ Pa) → Begin temperature ramp → Set a holding platform at 450-550°C (to allow the vacuum system to extract gases released by the workpiece and restore vacuum level) → Continue heating to brazing temperature while ensuring working vacuum meets specifications → Hold temperature → Cool.

How to Ensure Vacuum Levels for High Pass Rates: A Practical Guide

Pre-treatment is fundamental:

Cooling plate components must undergo rigorous degreasing, cleaning, and thorough drying. Any residual contaminants serve as sources of gas during heating, directly compromising the vacuum environment.

Equipment maintenance is essential:

Regularly clean the vacuum furnace chamber to prevent accumulated magnesium deposits from becoming a source of outgassing. Conduct regular leak inspections to ensure the furnace body remains sealed.

Process optimization is key:

Establish a reasonable heating schedule, set holding platforms within the temperature range of peak degassing, and allow sufficient time for the system to evacuate gases. Real-time monitoring of dynamic vacuum level curves, any abnormal fluctuations signal indicates a process issue.

Flux Selection:

For large cold plate with complex structures, a flux with slightly higher magnesium content may be selected to enhance membrane-breaking capability and furnace chamber purification capacity.

Summary on the Relationship Between Vacuum Level and Qualification Rate in Vacuum Brazing of Aluminum Cooling Plate

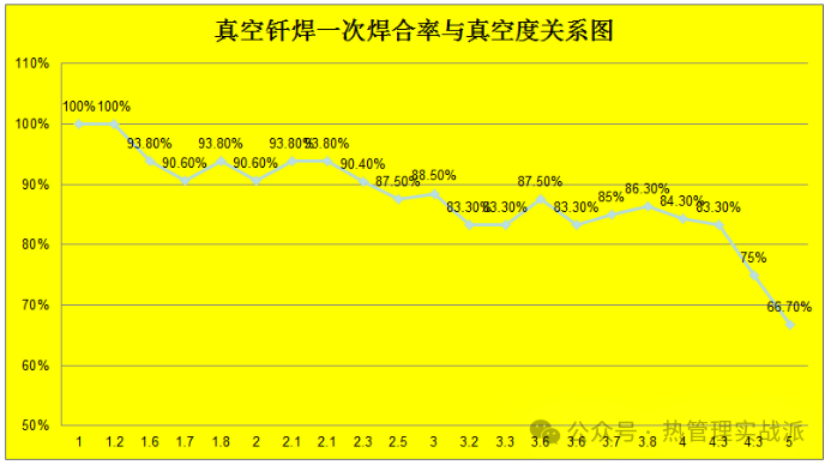

Through furnace-batch welding tests, the relationship between vacuum brazing joint qualification rate and vacuum level is shown in the table below (data represents relative values from welding records; variations exist due to environmental humidity and product differences, and are provided for reference only).

As shown in the table above, increasing vacuum pressure effectively improves the first-pass brazing success rate. Within a certain range, every 1×10⁻³ Pa reduction in vacuum pressure can boost the first-pass success rate by approximately 1.9%. Therefore, for vacuum brazing of aluminum cold plate, the relationship between vacuum pressure and pass rate can be summarized as:

High and stable vacuum level = Effective film-breaking capability + Pure brazing environment = Perfect solder spread, flow, and filling = Dense, leak-free, high-strength brazed joint = High pass rate.

Fluctuating or insufficient vacuum level = Failed film rupture + Ineffective magnesium consumption + Contamination and oxidation = Poor wetting, leakage, black discoloration = Batch-level scrap.

Therefore, precisely controlling and monitoring vacuum level as a core process parameter is the lifeline for successful aluminum liquid cooling plate production.