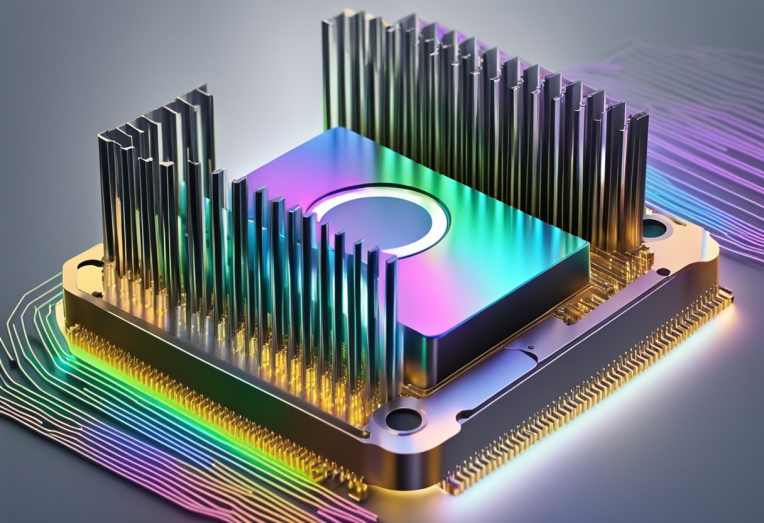

Aluminum heat sinks are an essential component in electronic devices that require cooling. They are designed to dissipate heat from electronic components, such as CPUs, GPUs, and power amplifiers, by transferring the heat to the surrounding air. The use of heat sinks has become increasingly important as electronic devices have become more powerful and compact, leading to higher levels of heat generation.

Aluminum is one of the most commonly used materials for heat sinks due to its excellent thermal conductivity, low cost, and lightweight properties. Aluminum heat sinks offer a range of benefits, including improved device performance, increased reliability, and extended lifespan. In addition, aluminum heat sinks can be customized to fit specific device requirements, such as size, shape, and thermal performance. This article will provide an introduction and guide to aluminum heat sinks, including their design, materials, manufacturing processes, and applications.

What is Aluminum Heat Sink

Basics of Aluminum Heat Sink

An Aluminum Heat Sink is a device used to dissipate heat from a hot surface to a cooler environment. It is made of aluminum, which is a good conductor of heat and has a high thermal conductivity. The heat sink is designed in such a way that it increases the surface area of the hot component, which in turn increases the rate of heat transfer.

Heat sinks are commonly used in electronic devices such as computers, LED lights, and power amplifiers, where heat is generated by the components. The heat sink absorbs the heat generated by the component and dissipates it to the surrounding environment, thereby preventing the component from overheating.

Importance of Aluminum Heat Sink

The use of Aluminum Heat Sink is important to prevent electronic devices from overheating, which can cause damage to the components and reduce their lifespan. Overheating can also lead to malfunctions and performance issues, which can affect the overall efficiency of the device.

Aluminum Heat Sink is preferred over other materials such as copper and steel due to its lightweight and cost-effectiveness. It is also corrosion-resistant and can withstand high temperatures, making it suitable for use in a wide range of electronic devices.

In summary, Aluminum Heat Sink is an important component in electronic devices that helps to dissipate heat and prevent overheating. Its use is essential to ensure the efficient performance and longevity of electronic devices.

Types of Aluminum Heat Sinks

Aluminum heat sinks are available in various types, each with its unique design and manufacturing process. The three most common types of aluminum heat sinks are extruded, stamped, and bonded fin heat sinks.

Extruded Heat Sinks

Extruded heat sinks are the most common type of aluminum heat sinks. They are produced by forcing aluminum through a die to create the desired shape. Extruded heat sinks are ideal for applications that require high fin densities, large surface areas, and complex shapes. They are also cost-effective and readily available.

Stamped Heat Sinks

Stamped heat sinks are produced by stamping aluminum sheets into the desired shape. They are ideal for applications that require low to medium fin densities, simple shapes, and low costs. Stamped heat sinks are also suitable for high-volume production.

Bonded Fin Heat Sinks

Bonded fin heat sinks are produced by bonding fins onto a base plate. They are ideal for applications that require high thermal performance and low weight. Bonded fin heat sinks are also suitable for applications that require high customization and low volume production.

In summary, each type of aluminum heat sink has its unique advantages and disadvantages. The choice of aluminum heat sink type depends on the specific application requirements, budget, and production volume.

How Aluminum Heat Sinks Work

Heat Transfer Process

Aluminum heat sinks work by transferring heat away from a source and dissipating it into the surrounding air. This process occurs through a combination of conduction, convection, and radiation.

Conduction is the transfer of heat through a solid material, such as the aluminum fins of a heat sink. Heat is conducted from the source to the fins, where it is then spread out across the surface area of the fins.

Convection is the transfer of heat through a fluid, such as air. As the heat spreads across the surface area of the fins, it heats up the surrounding air. The heated air rises and is replaced by cooler air, creating a continuous flow of air over the fins.

Radiation is the transfer of heat through electromagnetic waves. As the heat spreads across the surface area of the fins, some of it is radiated away into the surrounding environment.

Cooling Mechanism

Aluminum heat sinks work by increasing the surface area available for heat transfer. The fins of the heat sink are designed to provide a large surface area for the heat to dissipate into the surrounding air. The greater the surface area of the fins, the more effective the heat sink will be at dissipating heat.

To further increase the effectiveness of the heat sink, it is often paired with a fan. The fan blows air over the fins, increasing the rate of heat transfer through convection. This helps to keep the temperature of the heat sink and the source it is cooling at a lower temperature.

Overall, aluminum heat sinks are an effective and affordable way to dissipate heat from electronic components. By understanding the heat transfer process and cooling mechanism, you can choose the right heat sink for your application and ensure that your electronics stay cool and functioning properly.

Choosing the Right Aluminum Heat Sink

When it comes to choosing the right aluminum heat sink, there are several factors that need to be considered to ensure optimal performance. In this section, we will discuss some of the key factors to keep in mind, as well as some common mistakes to avoid.

Factors to Consider

Thermal Resistance

One of the most important factors to consider when choosing an aluminum heat sink is its thermal resistance. This refers to the ability of the heat sink to dissipate heat away from the heat source. The lower the thermal resistance, the more effective the heat sink will be at cooling the component.

Size and Shape

The size and shape of the heat sink also play a crucial role in its effectiveness. A larger heat sink will generally have a lower thermal resistance, but it may not be practical for all applications. The shape of the heat sink can also impact its performance, with fins and other features designed to increase surface area and improve heat dissipation.

Material and Coating

The material and coating of the heat sink can also impact its performance. Aluminum is a popular choice due to its high thermal conductivity and low cost. However, other materials such as copper and graphite may be more effective in certain applications. Coatings such as anodizing can also improve the heat sink’s performance and durability.

Common Mistakes

Overlooking Thermal Resistance

One common mistake when choosing an aluminum heat sink is overlooking the thermal resistance. It is important to choose a heat sink with a thermal resistance that is appropriate for the application to ensure optimal performance.

Choosing the Wrong Size or Shape

Choosing the wrong size or shape of heat sink can also lead to poor performance. It is important to consider the size and shape of the heat sink in relation to the component being cooled and the available space in the application.

Neglecting Material and Coating

Neglecting the material and coating of the heat sink can also lead to suboptimal performance. It is important to choose a material and coating that is appropriate for the application and can provide the necessary thermal conductivity and durability.

By keeping these factors in mind and avoiding common mistakes, it is possible to choose the right aluminum heat sink for any application.

Maintenance and Care of Aluminum Heat Sinks

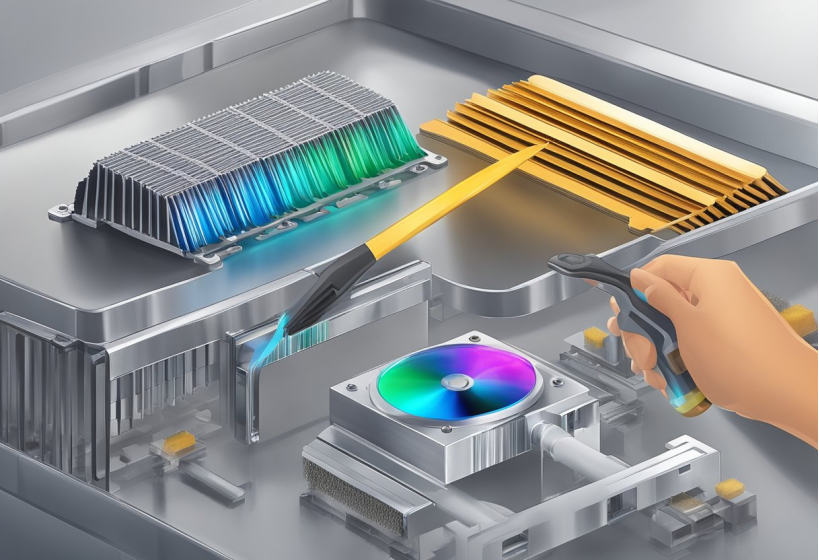

Aluminum heat sinks are widely used in various electronic devices to dissipate heat. To ensure their longevity and optimal performance, proper maintenance and care are necessary. Here are some tips to keep your aluminum heat sinks in good condition:

- Regular cleaning: Dust and other particles can accumulate on the surface of the heat sink, reducing its effectiveness. To prevent this, it is recommended to clean the heat sink periodically. Use a soft-bristled brush or compressed air to remove any dirt or debris. Avoid using water or any liquid cleaner, as it can damage the heat sink.

- Avoid physical damage: Aluminum heat sinks can be fragile, and any physical damage can affect their performance. Be careful while handling them, and avoid dropping or hitting them against hard surfaces.

- Check for corrosion: Aluminum heat sinks can corrode over time, especially in humid environments. Check for any signs of corrosion, such as discoloration or pitting, and replace the heat sink if necessary.

- Proper installation: Ensure that the heat sink is installed properly, with sufficient thermal paste or adhesive to ensure good contact with the heat source. Improper installation can lead to poor heat dissipation and reduced performance.

By following these simple tips, you can ensure that your aluminum heat sinks provide optimal performance and last for a long time.