Liquid cooling plates have revolutionized thermal management in industrial applications. As industries evolve, the need for efficient and reliable cooling solutions becomes paramount. This article delves into the latest innovations in liquid cooling plates, exploring their benefits, applications, and the role of PTHeatsink in advancing this technology.

What Are Liquid Cooling Plates?

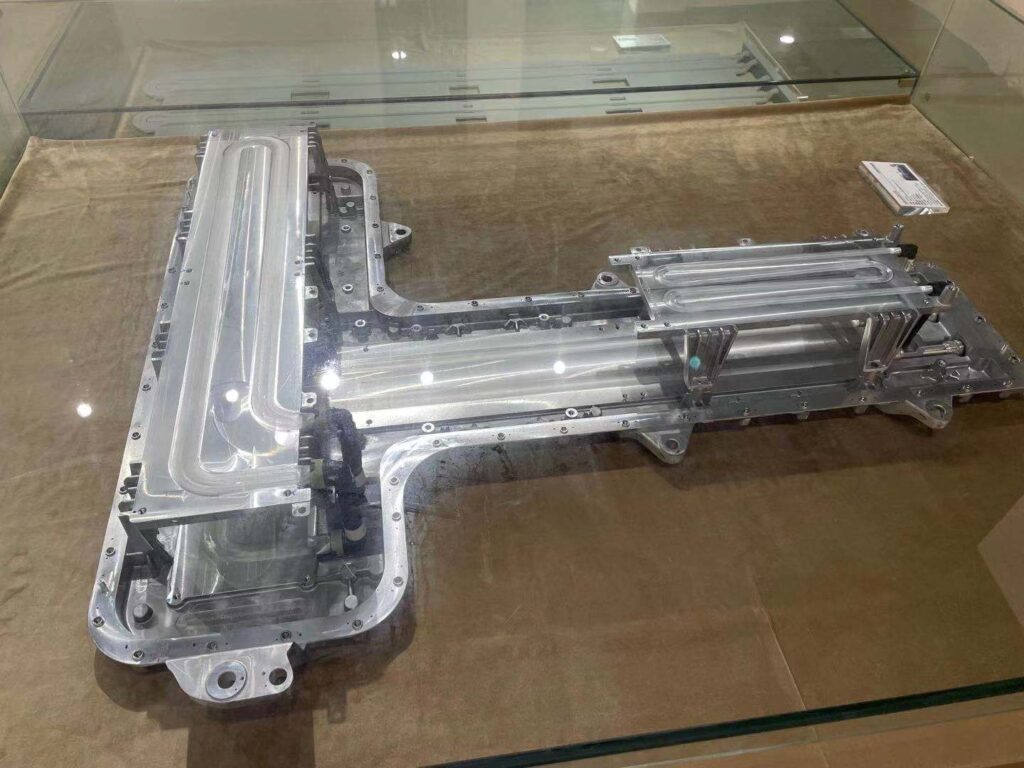

Liquid cooling plates are crucial in managing heat in various industrial settings. They are flat components with internal channels through which a cooling liquid circulates. Made from materials like copper and aluminum, these plates efficiently transfer heat away from critical components, ensuring optimal performance and longevity.

How Liquid Cooling Plates Work

The working principle of liquid cooling plates is straightforward. The cooling liquid absorbs heat from the surface it contacts and carries it away through internal channels. This process relies on fluid dynamics, which involves the study of how liquids move and transfer heat. By designing these channels efficiently, engineers can maximize the cooling capacity of the plates.

Advancements in Liquid Cooling Technology

Innovative Design and Materials

Recent advancements include using high-conductivity materials like graphene and enhanced aluminum alloys. These materials improve thermal performance and reduce the weight of cooling systems.

Manufacturing Techniques

Advanced manufacturing techniques such as CNC machining, extrusion, and cold forging allow for precise and efficient production of cooling plates. Methods like skiving fin and heat pipe assembly further enhance the cooling capacity.

Smart Cooling Systems

Integrating Artificial Intelligence (AI) and the Internet of Things (IoT) into cooling systems allows for real-time monitoring and optimization. These smart systems can adjust cooling parameters based on operational needs, improving efficiency and reliability.

Benefits of Liquid Cooling Plates

Enhanced Cooling Efficiency

Liquid cooling provides superior thermal management, as liquids can absorb and transfer heat more effectively than air. This efficiency is crucial for high-performance applications where maintaining optimal temperatures is critical.

Energy and Cost Efficiency

By reducing the need for large, energy-intensive air cooling systems, liquid cooling plates can significantly lower energy consumption and costs. This efficiency translates into long-term savings for industrial operations.

Reliability and Durability

Liquid cooling systems are more reliable and durable than their air-cooled counterparts. They require less maintenance and are less prone to failure, making them ideal for critical applications in industries like data centers and medical equipment.

Applications in Various Industries

Automotive

In the automotive industry, liquid cooling plates are used to manage the heat generated by electric vehicle (EV) batteries and power electronics. Efficient cooling ensures optimal performance and extends the lifespan of these components.

Data Centers and Computer Servers

Data centers and computer servers generate significant heat, requiring effective cooling solutions. Liquid cooling plates help maintain ideal temperatures, ensuring reliable operation and preventing downtime.

Medical Equipment

Medical devices such as MRI machines and laser equipment generate heat during operation. High-quality liquid cooling plates help maintain safe operating temperatures, ensuring the reliability and safety of critical devices.

Telecommunication and AI

Telecommunication equipment and AI processing units also benefit from liquid cooling plates. These systems require constant cooling to function correctly, and liquid cooling plates provide an efficient solution.

Future Trends in Liquid Cooling

Emerging Technologies

Nanotechnology and advanced materials like graphene are expected to enhance the thermal performance of cooling plates further. Additionally, the integration of AI and IoT will lead to smarter, more efficient cooling systems.

Sustainability and Environmental Impact

Eco-friendly materials and manufacturing processes are becoming increasingly important. Innovations aimed at reducing the carbon footprint of cooling systems are crucial for sustainable industrial practices.

Liquid cooling plates are essential for efficient thermal management in various industrial applications. The continuous innovation in design, materials, and manufacturing techniques ensures that these cooling solutions remain effective and reliable. PTHeatsink’s contributions to this field demonstrate the potential for high-quality, cost-effective thermal solutions. As industries continue to evolve, the importance of advanced cooling technologies will only grow.

Frequently Asked Questions

What are liquid cooling plates and how do they work?

Liquid cooling plates are flat components with internal channels for circulating a cooling liquid. They work by absorbing heat from the surface they contact and transferring it away through the liquid.

What are the benefits of using liquid cooling plates over traditional air cooling methods?

Liquid cooling plates offer enhanced cooling efficiency, energy and cost savings, and increased reliability and durability compared to air cooling methods.

Which materials are commonly used in the manufacturing of liquid cooling plates?

Common materials include copper and aluminum, known for their excellent thermal conductivity.

How do innovations in liquid cooling technology impact industrial applications?

Innovations improve the efficiency, reliability, and cost-effectiveness of cooling solutions, benefiting industries like automotive, data centers, and medical equipment.

Can liquid cooling plates be used in automotive applications?

Yes, they are used to manage the heat generated by electric vehicle batteries and power electronics.

What role do smart cooling systems play in modern data centers?

Smart cooling systems use AI and IoT to optimize cooling parameters in real-time, improving efficiency and reliability.

How does PTHeatsink ensure the quality and reliability of its cooling plates?

PTHeatsink uses advanced manufacturing techniques and stringent quality control processes to ensure high-quality products.

What are the energy and cost benefits of using liquid cooling plates in industrial settings?

Liquid cooling plates reduce the need for large, energy-intensive air cooling systems, leading to significant energy and cost savings.

How do liquid cooling plates contribute to the reliability and safety of medical equipment?

They help maintain safe operating temperatures, ensuring the reliability and safety of medical devices.

What are the future trends in liquid cooling technology?

Future trends include the use of nanotechnology, advanced materials, and the integration of AI and IoT for smarter cooling systems.

What specific cooling solutions does PTHeatsink offer for high-performance computing environments?

PTHeatsink offers advanced liquid cooling plates and other thermal management solutions designed for high-performance computing environments.

How does PTHeatsink customize cooling solutions to meet specific industrial needs?

PTHeatsink works closely with clients to understand their unique requirements and uses advanced design and manufacturing techniques to create customized solutions.

Can PTHeatsink provide examples of successful implementations of their cooling plates?

Yes, PTHeatsink has numerous case studies and customer testimonials showcasing the successful implementation of their cooling solutions.

What is the process for getting a custom-designed cooling solution from PTHeatsink?

Interested customers can contact PTHeatsink to discuss their needs, after which PTHeatsink’s engineering team will design, prototype, and produce the custom cooling solution.