Friction Stir Welding (FSW) is an innovative solid-state joining technology particularly suited for manufacturing thermal management products (such as liquid cooling plates, heat sinks, cold modules, battery pack enclosures/liquid cooling plates, etc.). It plasticizes and joins materials through mechanical stirring and frictional heat, avoiding the drawbacks of traditional fusion welding and offering significant advantages in thermal management applications.

Working Principle of Friction Stir Welding Technology

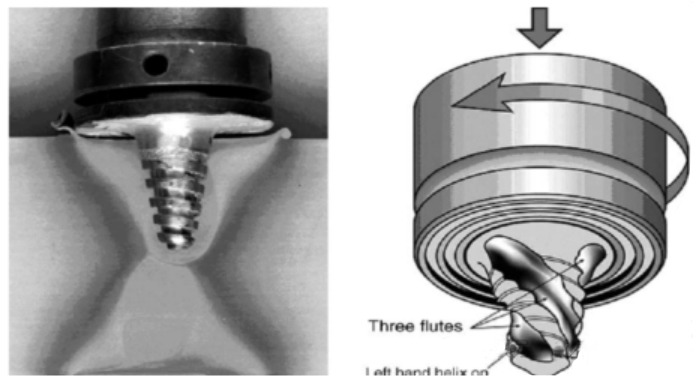

- Tooling: Utilizes a specially designed, high-speed rotating friction stir tool. It consists of a shoulder and a stir pin.

- Process: The stir pin is inserted into the joint between the workpieces to be welded, with the shoulder contacting the workpiece surface. Under high-speed rotation and axial pressure, friction generates heat. The friction between the stirrer and the material produces heat, softening the material in the contact area to a plastic state (below the melting point)

Stirring and Forging: The rotating stirrer intensely stirs the plasticized material, while the pressure from the shoulder “forges” the material together.

Weld formation: The stirrer head moves along the welding direction, continuously plasticizing, stirring, and extruding material forward. Upon cooling, this forms a dense solid-state weld.

2.1 Liquid Cooling Plates (Water-Cooled Plates): This is the most classic application of FSW. It is used for welding cover plates and base plates of liquid cooling channels, joining extruded profile channels, and welding plugs.

Advantages: High weld strength, excellent sealing (zero leakage), smooth channel inner walls free of spatter/slag (minimal impact on flow resistance), low distortion, and capability to weld large-area plates.

2.2 Radiator/Fin Heat Sink Substrates: Used to weld fin arrays onto substrates or create complex internal flow channels

2.3 Battery Pack Thermal Management Components:

Battery Tray/Enclosure: Welding aluminum alloy enclosure side panels to the base plate, achieving high strength, excellent sealing, and no porosity

Battery Module Liquid Cooling Plates: Similar welding requirements to liquid cooling plates, with extremely high leak prevention demands.

2.4 Power Electronics Coolers (e.g., IGBT Water-Cooled Heatsinks): Welding housings with intricate flow channels to ensure pressure resistance and sealing integrity.

Comparative Analysis of Friction Stir Welding vs. Traditional Welding Technologies in Thermal Management

For thermal management products, the comparative advantages of friction stir welding versus traditional welding technologies are summarized in the table below:

| Characteristic | Friction Stir Welding | Traditional Fusion Welding (e.g.,TIG/MIG) | Brazing | Adhesive/Sealant |

| Heat input | Low, concentrated ,solid-state process | High, widely distributed, complete melting | Moderate, flux melting | Room temperature or heat curing |

| Micro structure | Fine-grained structure, excellent mechanical properties | Casting structure, coarse grains, prone to porosity and cracks | Interface diffusion layer present | Only physical/chemical bonding |

| Strength | High joint strength (reaching 70%-95% of base metal) | Lower strength, softening in the heat-affected zone | Strength depends on filler metal, typically low | Low strength, prone to degradation after aging |

| Sealing performance | Excellent, dense and defect-free | May contain microscopic pores leading to slow seepage | Good, but dependent on flux flow | Material-dependent, long-term stability questionable |

| Deformation | Minimal, requiring little subsequent machining | Significant deformation, prone to warping | Minimal deformation | No thermal deformation |

| Internal welding quality | Smooth with no spatter/slag,low flow resistance | Prone to weld nodules and spatter, requiring internal cleaning | Flux may clog flow channels | Not applicable |

| Material | Significant advantages for aluminum alloys (especially Series 2, 6, and 7); also welds copper, magnesium, etc. | Wide range of weldable materials, but aluminum alloys are prone to defects | Suitable for multiple materials | Broad applicability, but limited by adhesive compatibility |

| Environmental and Safety | No fumes, arc light, or spatter; environmentally friendly and safe | Produce fumes, intense light, requires protective gear | May require flux, presents cleaning issues | Potential volatile emissions |

| Energy consumption | Relatively low | Higher | Moderate | Low |

Challenges and Limitations of Friction Stir Welding in Thermal Management Applications

4.1 High Initial Investment: FSW equipment is costly.

4.2 Workpiece Requirements: Significant clamping force is required to secure workpieces, require complex fixture design.

4.3 Welding Speed: Compared to certain high-speed fusion welding processes, FSW does not achieve the fastest welding speeds.Weld Termination: A “keyhole” is left on the workpiece, typically requiring process design to position it in non-critical areas.

4.4 Flexibility: Less adaptable than robotic arc welding for complex three-dimensional curves, though this is improving with advancements in robotic FSW.

Development Trends in Friction Stir Welding Technology

5.1 Robotic FSW:Enhancing flexibility formorecomplex3Dgeometries (e.g.,irregular liquid cooling plates).

5.2 Keyhole-free technology: Dynamically adjustable friction stir tools enable hole-free start/stop points, enhancing product integrity.

5.3 Dissimilar Material Joining: Enables aluminum-copper connections for power electronics heat dissipation.Online Monitoring and Intelligence: Integrated force control, temperature, and process monitoring ensure consistent weld quality.

5.4 Derivative Technologies:

Friction Stir Spot Welding: Replaces resistance spot welding.

Friction Stir Additive Manufacturing: Used for manufacturing or repairing thermal management structures

For thermal management products demanding high performance, reliability, and zero leakage (especially components involving liquid circulation), friction stir welding has emerged as the industry-leading manufacturing process. Despite its higher upfront investment, its exceptional weld quality, minimal distortion, and high consistency significantly enhance product lifespan and performance while reducing overall costs. It is increasingly becoming the standard process in high-end thermal management applications such as high-power electronics, new energy vehicles, and aerospace.