Incomplete welds in vacuum brazing of plate-fin cooling plate are one of the main defects in production, which seriously affect the cold plate’s sealing performance, strength, and heat dissipation efficiency. Without considering raw material and tooling factors, the main causes of incomplete welds in vacuum brazing can be attributed to: insufficient interface cleanliness, poor fit clearance, and improper control of core process parameters such as brazing temperature, time, and vacuum degree.

1. Part cleanliness and assembly clearance factors

1.1 Insufficient Cleanliness:

Oil Stains: Lubricating oil and rust-preventive oil from stamping and machining processes.

Oxide Film: The natural oxide film (Al₂O₃) on the base material (usually aluminum alloy, such as 3003) and the surface of the brazing filler. This oxide film is very dense and stable, severely hindering the wetting and spreading of the filler.

Other Contaminants: Dust, fingerprints, moisture, etc.

Consequences: Contaminants form a barrier, preventing direct atomic contact between the liquid filler and the base material, leading to brazing agglomeration, lack of spreading, and ultimately, a cold brazing joint.

1.2 Improper component clearance:

Excessive clearance: Capillary action is weakened, making it impossible to effectively draw and retain molten brazing filler in the gap, leading to brazing loss or incomplete filling, resulting in voids.

Uneven clearance: Due to component machining precision or assembly issues, local clearances may be too large or too small, causing both of the above problems to occur simultaneously on the same product.

2. Process parameter factors

This is the core of vacuum brazing; improper parameter settings will directly lead to a cold brazing joint.

2.1 Brazing Temperature:

2.1.1 Too Low Temperature: The brazing filler metal fails to melt completely or lacks sufficient fluidity, failing to adequately wet and fill the gaps.

2.1.2 Too High Temperature: The base metal grains grow excessively, leading to decreased mechanical properties.

2.1.3 Excessive volatilization and loss of the brazing filler metal result in a lean weld seam.

2.1.4 This may lead to localized melting (erosion) of the base metal.

2.1.5 Uneven Temperature: Uneven temperature field within the furnace causes asynchronous melting of the brazing filler metal in different areas of the product; some areas are already wetted and spread, while others remain unmelted.

2.2 Holding time:

Insufficient time: Insufficient interaction (dissolution, diffusion) between the brazing filler metal and the base metal, resulting in weak metallurgical bonding.

Excessive time: Similar to the consequences of “excessive temperature,” it can also lead to brazing filler metal loss, base metal erosion, and coarse grains.

2.3 Vacuum Degree:

Insufficient Vacuum Degree: This is a critical factor in vacuum brazing. Residual oxygen and water vapor inside the furnace will cause secondary oxidation of the aluminum during heating, reforming a dense oxide film and compromising the wettability of the brazing filler metal. This is a unique and extremely important factor in vacuum brazing.

Leakage Rate: If there are leaks in the vacuum furnace, outside air will continuously seep in during the heat preservation process, also causing oxidation.

2.4 Heating and cooling rates:

Heating rate too slow: Excessive dwell time in the sensitive temperature range (approximately 300-500°C) provides opportunities for oxidation of the base metal and brazing surfaces.

Heating rate too fast: May result in excessively large temperature gradients within the multilayer structure, generating thermal stress, or causing the volatilization of low-melting-point components in the solder.

Cooling rate: Affects the crystallization and phase composition of the brazed joint microstructure; excessively slow cooling may lead to the growth of brittle phases.

3. Analysis and solutions to welding defects

When a cold solder joint occurs, it is recommended to follow these steps:

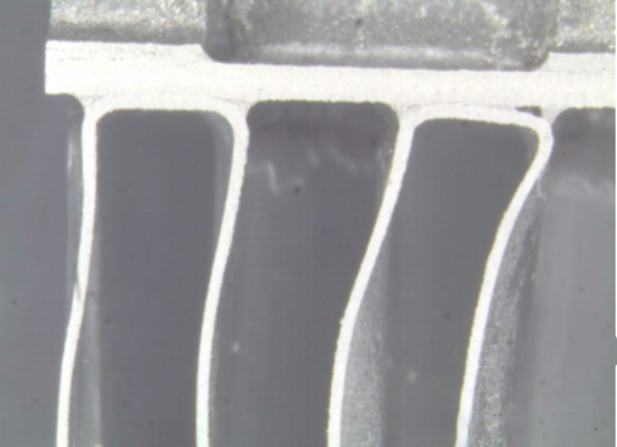

3.1 The specific location of the cold brazing joint can be determined using methods such as X-ray and ultrasonic testing.

Dissect the failed samples, and the microstructure of the cold solder joint interface can be observed using metallographic microscopy and scanning electron microscopy (SEM) to analyze the brazing filler spread, the presence of oxides, and the thickness of the interface reaction layer.

3.2 Systematic Inspection:

Check Pre-treatment Records: Confirm that the cleaning process was strictly followed and that the cleaning solution concentration and temperature were within acceptable ranges.

Verify Raw Materials: Check the material certificates for the brazing filler metal and base metal, and confirm the brazing filler metal arrangement plan and quantity.

Analyze Process Curves: Retrieve the temperature-vacuum-time curve for this furnace run and compare it with a mature and stable process curve, focusing on the heating phase, brazing temperature plateau, and vacuum level.

Inspect Equipment and Tooling: Confirm the vacuum furnace leak detection records and furnace temperature uniformity test report. Check the tooling for deformation or contamination.

3.3 Corrective and preventative measures:

Address the root cause by implementing corrective actions such as optimizing the cleaning process, adjusting the brazing placement, revising process parameters, repairing equipment, or replacing tooling.

Establish a rigorous process control system to monitor and record key processes (such as cleaning, assembly, and brazing).