Here’s how heat pipe cooling is quietly transforming the way thermal management operates in some of the world’s most demanding industries.

When we discuss high-performance systems in cars, planes, and even medical equipment that saves lives, overheating isn’t just a nuisance; it’s a danger. That’s when cooling with heat pipes comes in. This effective way of managing heat isn’t new, but its importance has increased significantly in recent years, particularly in mission-critical settings.

As machines and electronics get smaller and more powerful, it gets harder to keep them cool. Heat pipes quickly transfer heat away from sensitive components, allowing them to operate at optimal temperatures without requiring extensive, power-hungry systems. This technology provides stable thermal performance without any trade-offs, whether you’re creating a battery pack for an electric car. This drone operates at high altitudes, like an MRI machine.

How Heat Pipe Technology Supports High-Demand Applications

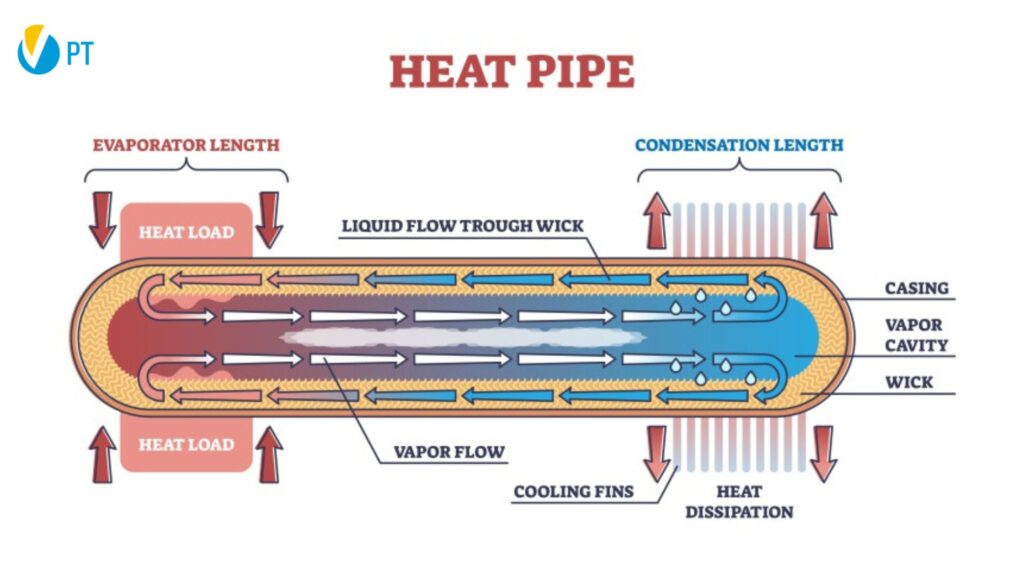

The idea behind heat pipes is simple: they utilize the phase change of a working fluid, such as water or ammonia, within a sealed tube to transfer heat from one end to the other. However, the best part is how quickly and effectively they accomplish this, as well as their excellent performance across different platforms.

They handle the heavy thermal load of EV batteries and power electronics in automotive systems. They offer lightweight thermal control without moving parts in aerospace, where weight and dependability are everything. In medical technology, where safety and accuracy are crucial, they help maintain the optimal temperature for sensitive imaging and diagnostic equipment.

Keeping EVs Cool and Safe in Cars

Thermal design has become increasingly challenging due to the growing number of electric cars on the road. Heat sink makers know this. In modern electric vehicles, where batteries, inverters, and motors generate significant heat in confined spaces, heat pipe cooling is now a crucial component.

This essentially means that these cars and trucks could perform significantly worse and last significantly less time without an effective way to dissipate heat. Cooling plates or aluminum heat sinks can have heat pipes built into or added to them to quickly and evenly dissipate heat.

It’s not just about keeping things from getting too hot. Managing temperature stably enables batteries to last longer, charge faster, and makes the entire system safer. That’s something you need in a market where performance and dependability are essential.

Aerospace: Lightweight and dependable temperature control

In aerospace applications, managing heat efficiently is more critical than anywhere else. Satellites, spacecraft, and high-altitude UAVs (unmanned aerial vehicles) operate in areas where convection, the primary method of heat transfer, is almost nonexistent.

This is when heat pipe cooling really shines. It works without air or gravity, making it ideal for locations with minimal or no gravity and limited air supply. Systems need to be lightweight yet able to withstand significant temperature fluctuations. That’s a lot to ask, but heat pipes can do it.

Many people are unaware that a growing number of heat sink manufacturers are now producing hybrid assemblies that incorporate heat pipes directly into aluminum or copper fins. These units are ideal for avionics and onboard processors due to their compact size, which provides structural stability and effective cooling.

Medical Tech: Quiet accuracy with no room for mistakes

CT scanners, MRI systems, and robotic surgical tools are examples of medical equipment that make a lot of heat in small, closed spaces. Fans that are not electronic make noise and cause vibrations, which are not good in clinical settings.

Heat pipes are a quiet, vibration-free method for cooling devices that fit seamlessly into small spaces. Additionally, maintaining a stable temperature is crucial in medical imaging. Even small changes in temperature can change the results. Heat pipe cooling systems create a stable environment that is necessary for accurate diagnostics.

Why Heat Pipe Cooling Is Important: Final Thoughts

We don’t need to make it more complicated. This is what matters: heat pipe cooling effectively solves problems in the automotive, aerospace, and medical fields. It provides consistent, passive, and effective temperature control where other methods fail. It achieves this with minimal weight, no moving parts, and a long lifespan.

As the need for accuracy, portability, and power increases, designers are increasingly utilizing this tried-and-true thermal technology. The best heat sink companies don’t just sell parts; they also provide comprehensive solutions. They are making solutions that work with these new apps.

FAQs

What is the process of heat pipe cooling?

A sealed fluid that evaporates at the heat source and condenses at the cooler end is how heat pipes move heat. This cycle transfers heat energy quickly without requiring any external power.

Are heat pipes better than regular fans?

Yes, in many cases. There are no moving parts in heat pipes, and they last longer. They’re invaluable in places where fans make excessive noise, disrupt the atmosphere, or fail to work well.

Where do people usually use heat pipes?

You can find them in batteries for electric vehicles, satellites, electronics for planes, medical imaging equipment, gaming laptops, and telecom hardware.

Are heat pipes able to handle very high temperatures?

Yes. Heat pipes can work in temperatures from -60°C to over 250°C, depending on the working fluid. This makes them suitable for use in aerospace and industrial settings.